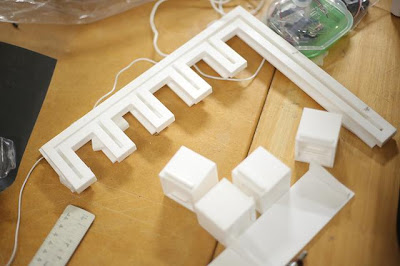

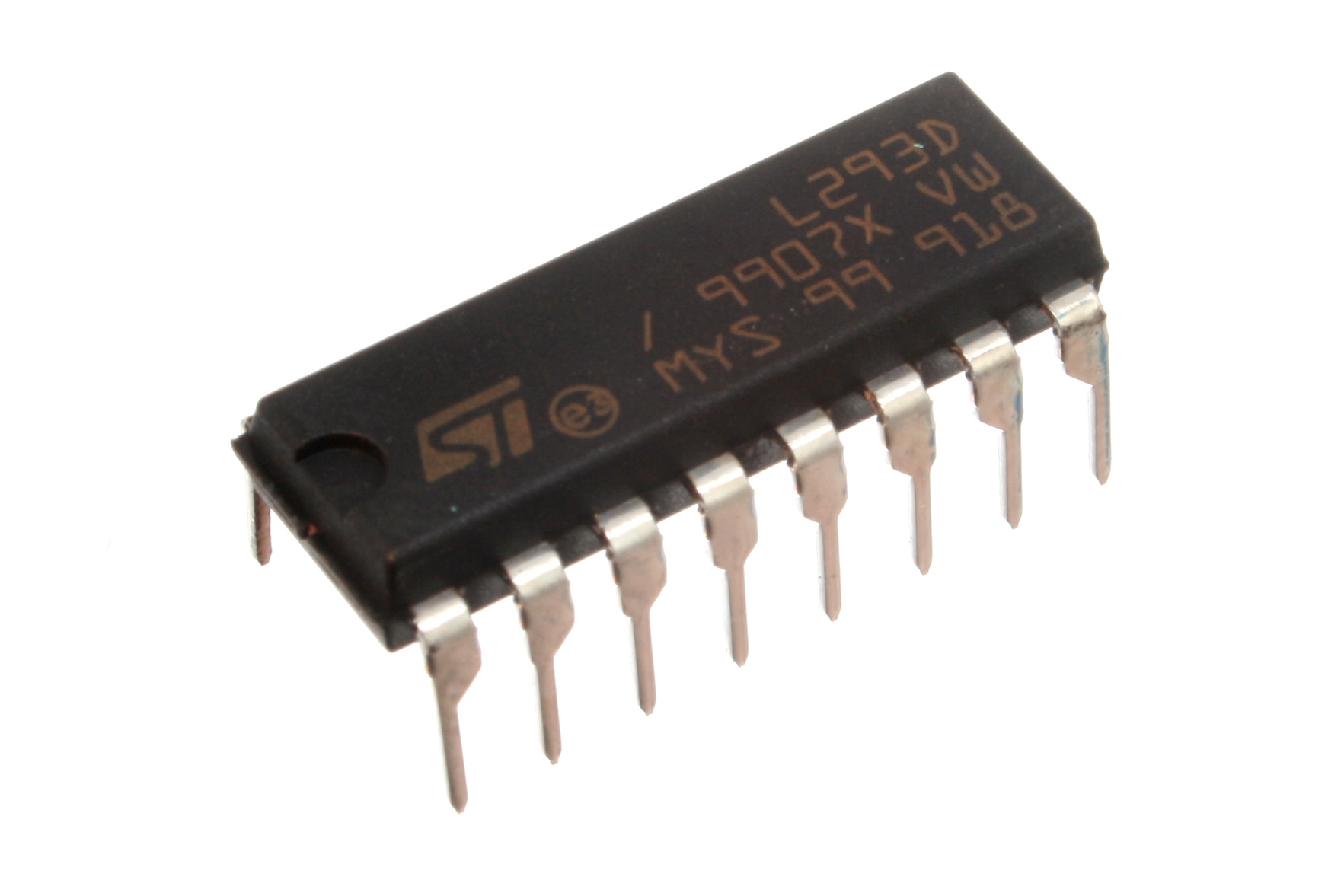

What I have now is the 2 L293D motor driver to control each motor by the push button. There are two push button to control each motor. While one motor is rotating the other will be disabled and while the other is push will work other wise. The reason to separate the two DC motor is becasue of the power supply. In this circuit the power from 9V battery is supplied separately. (See below Diagram)

There are also another push button to control the direction of the full rotation servo. Once the button is pressed servo will rotate clockwise after a set time it will then rotate counter clockwise for a certain seconds

Video below shows how to servo works with the push button.

Video From: http://www.youtube.com/watch?v=Kg2LExR3s9M

Another push button is also installed to control the standard servo this one will act as a switch for electromagnet. At this stage we can not find the way to make a magnet stronger. Therefore we will not be putting it in the prototype.

The following is the code applied in the Arduino Application.

#include <Servo.h> //include servos in the code

Servo servoMain; //identify servo as a main servo

Servo servoSwitch; //identify servo as a switch servo for eletromagnet

int switchPin = 1; //push button pin for motor to go left

int switch2Pin = 2; //push button pin for motor to go right

int servoSwitchPin = 4; //push button pin for electrmagnet switch

int mainServoLongPin = 7; //push button pin for main servo to move down

int mainServoUpPin = 8; //push button pin for main servo to move up

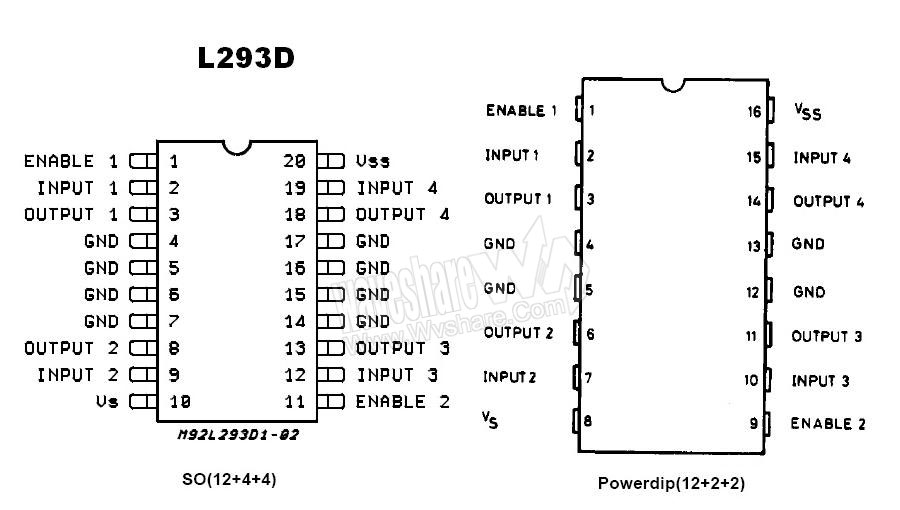

//pin for L293D H-bridge motor drive

//left motor

int motor1Pin1 = 6; // pin 2 on L293D

int motor1Pin2 = 11; // pin 7 on L293D

int enablePin = 5; // pin 1 on L293D

//right motor

int motor2Pin1 = 10; // pin 2 on L293D

int motor2Pin2 = 9; // pin 7 on L293D

int enable2Pin = 3; // pin 1 on L293D

void setup() {

pinMode(switchPin, INPUT); //set left push button as an input

pinMode(switch2Pin, INPUT); //set right push button as an input

pinMode(servoSwitchPin, INPUT); //set main servo push button as an input

pinMode(mainServoLongPin, INPUT); //set main servo push button to move down as an input

pinMode(mainServoUpPin, INPUT); //set main servo push button to move up as an input

//set L293D pins as output pins for left motor

pinMode(motor1Pin1, OUTPUT);

pinMode(motor1Pin2, OUTPUT);

pinMode(enablePin, OUTPUT);

//set L293D pins as output pins for right motor

pinMode(motor2Pin1, OUTPUT);

pinMode(motor2Pin2, OUTPUT);

pinMode(enable2Pin, OUTPUT);

//set the enable pin from IC to motors as an 'off'/ disable motors

digitalWrite(enablePin, LOW); //disable left motor

digitalWrite(enable2Pin, LOW); //disablr right motor

}

void loop() {

//if this button is pressed

//the switch servo rotate to 0/ 180 position

if (digitalRead(servoSwitchPin) == HIGH) {

servoSwitch.attach(13); //activate switch servo

servoSwitch.write(180); //tell servo to go to 180 position

delay(3000); //stay for 5 seconds

}

//if the button is not pressed

else {

servoSwitch.write(0); //servo go back to 0 position

}

//if this button is pressed

//main servo rotate clockwise

//goes down and stop

if (digitalRead(mainServoLongPin) == HIGH) {

servoMain.attach(12); //activate main servo

servoSwitch.detach();

servoMain.writeMicroseconds(1700); //main servo rotate clockwise

delay(100);

}

//if the button is not pressed

else {

servoMain.detach(); //deactivate main servo

}

//if this button is pressed

//main servo rotate anti-clockwise

//goes up and stop

if (digitalRead(mainServoUpPin) == HIGH) {

servoMain.attach(12); //activate main servo

servoMain.writeMicroseconds(1300); //rotate anti-clockwise

delay(100);

}

//if the button is not pressed

else {

servoMain.detach(); //deactivate main servo

}

//if this button is pressed

//enable left motor

//rotate for 2 seconds and stop

if (digitalRead(switchPin) == HIGH) {

digitalWrite(motor1Pin1, LOW); // set pin 2 on L293D low

digitalWrite(motor1Pin2, HIGH); // set pin 7 on L293D high

digitalWrite(enablePin, HIGH); // set pin 1 on L293D high

}

//if this button is not pressed

//disable all the pins

//deactivate motor

else {

digitalWrite(motor1Pin1, LOW); // set pin 2 on L293D low

digitalWrite(motor1Pin2, LOW); // set pin 7 on L293D low

digitalWrite(enablePin, LOW); // set pin 1 on L293D low

}

//if this button is pressed

//enable right motor to rotate in opposite direction

//rotate for 2 seconds and stop

if (digitalRead(switch2Pin) == HIGH) {

digitalWrite(motor2Pin1, HIGH); // set pin 2 on L293D high

digitalWrite(motor2Pin2, LOW); // set pin 7 on L293D low

digitalWrite(enable2Pin, HIGH);// set pin 1 on L293D high

}

//if this button is not pressed

//disable all the pins

//deactivate motor

else {

digitalWrite(motor2Pin1, LOW); // set pin 2 on L293D low

digitalWrite(motor2Pin2, LOW); // set pin 7 on L293D low

digitalWrite(enable2Pin, LOW); // set pin 1 on L293D low

}

}

.JPG)